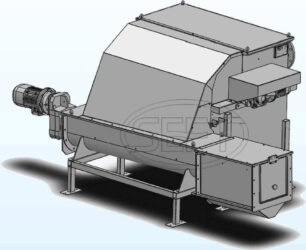

Combined Wastewater pre-treatment Unit

Combined Wastewater Pre-treatment Unit

GDE performs: screening, sand removal. GDE/D performs: screening, sand removal, oil/fat removal.

Can be supplied in 2 models: • CLS sand classifier + FCP/C screw screen in tank, with perforated rounded or wedge wire profile.

• CLS sand classifier + GRR drum filter, with wedge wire profile. Based on the chosen model, it will be possible to get a different type of screening.

The sewage goes through the screening section for the solid parts removal. Then the sewage falls down a decantation tank where the particles go down. Here an extraction spiral removes them.

FUNCTIONS

• Screening

• washing/compacting of solid removed

• sand/grit separation

• degreasing

MAIN ADVANTAGES

• Odor-free • No clogging

• Low maintenance and operation costs

• Low room needed • No construction works needed

• Easy to install and operate

• Very low residual organic content in the washed out solid

• Volume reduction (up to 40%) of the washed out solid

• Sand removal: >=90% of particles up to 200 μ

MANUFACTURING FEATURES

Building material External structure: stainless steel AISI304L/AISI316L

Screw: HSS carbon steel or ss AISI

304L/AISI316L

Flow rate range 6 or 10 l/s

Inlet pipe Flanged

APPLICATIONS

• Municipal sewage

• Industrial wastewater treatment